Output quality control

Quality is the main pillar of our corporate culture and vision. In specialized industries such as ours, if we didn't create durable, precise, and beneficial products for our users, we certainly wouldn't last 30 years. Firefighters, military, police, and paramedics place a huge emphasis on perfect workmanship in their jobs and their expectations are the highest. For many years now, we have been able to meet these demands and also develop innovations that appeal to them and, above all, work.

Every piece is checked at our production in Štípa and the main goal is...

to get a product for our everyday heroes that won't let them down and will protect them.

Each piece goes through the following stages of inspection:

- Visual inspection to make sure everything looks as it should in terms of colour and shape.

- Seam checking is an integral part, where the glove is turned over and all the internal seams are monitored.

- The quality of the materials is checked during regular full-piece texts or certifications.

- The membranes are checked on a special machine for each glove.

- Monitoring compliance with standards is the next step.

Finally, each piece comes with a label and a leaflet to inform the end user.

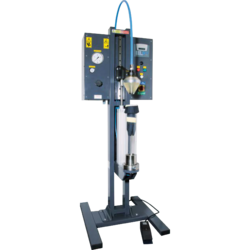

Membrane testing

A unique device developed by Holík International s.r.o. used to test the integrity (intactness) of membrane inserted in finished gloves.

The machine is able to test the glove (the membrane liner in the glove) and determine if the membrane is intact. It works on the principle of detecting holes and other material defects that may have occurred during the manufacture of the membrane, but especially during the manufacture of the glove.

Features:

- Tests the finished glove.

- Able to detect the slightest hole or damages in the membrane.

- Equipped with an indication of the size of the founded hole/damage.

- Designed to test all types of membrane gloves across the entire size range.

- The device gives an unambiguous result with 100% reliability, no misinterpretation of the measurement result by the machine operator.

- Records the number of gloves tested - bad and good.

- It is a dry test unlike other membrane testing methods.

EN ISO 9001 / EN ISO 14001

EN ISO 9001:2016

Quality management system

This is a system-oriented standard that defines the requirements for a company's management system. The result is management processes that are stable and produce quality products or services.

EN ISO 14001:2016

Environmental Management System (EMS)

This is a system-oriented standard that defines the requirements for a company's environmental management system. It results in knowledge of and compliance with environmental requirements, a system for improving the company's environmental performance and preventing environmental accidents.

Within the internal company processes, we follow the valid and recognized ISO 9001 standard. This methodology is followed from the purchase of materials, the selection of suppliers or their products, to the output quality control. The transfer of information from development to production and the technical preparation of production are also an integral part of this.

Further information is available for download below.

Allied Quality Assurance Publications (AQAP)

AQAP certification confirms that an organisation meets the requirements set by the Allied Quality Assurance Publications (AQAP) standards. These standards are issued by NATO and are intended for quality management systems in the defence and military sectors. AQAP certification focuses on quality assurance in the production, development and delivery of defence products or services.