PORON®XRD™

PORON®XRD™ is an intelligent, high-impact-absorbing foam brace filler patented in the USA. The material absorbs up to 90% of impact and repeatedly forms a protective shell. Combined with its low profile, lightweight, and flexibility, it is the ideal absorbent for firefighting and tactical gloves. Now our main supplier is Omnipel Technologies, based in Italy.

Usage:

- Manufacture of firefighting gloves.

- Production of tactical gloves.

Features:

- High level of shock absorption - perfect shock absorption.

- Lightweight - apart from its light weight, it is soft and comfortable.

- Flexibility - returns to its original shape after shock absorption.

- Intelligent properties - upon impact, the molecules lock and solidify.

- Breathability.

D3O® Impact protection material

An intelligent protective material developed and patented by D3O® in the UK. Its perfect shock absorption, lightness and flexibility make it the material of choice for firefighting and tactical gloves. A special feature is the thin design, while important properties remain intact. Its perfect shock absorption, lightness and flexibility make it the material of choice for firefighting and tactical gloves.

Usage:

- Production of tactical military and anti-strike gloves.

- Manufacture of firefighting gloves.

Features:

- Lightweight - apart from light weight, it is soft and comfortable.

- Flexibility - returns to its original shape after absorbing impact.

- High level of protection - perfectly absorbs impacts.

- Intelligent properties - upon impact, the molecules lock and solidify.

Impacton® Impact knuckle

Special polyurethane knuckle guard with PU memory foam cushioning "HERATROM", which is a durable and highly flexible material produced by Impacton® of South Korea. It is another alternative in the production of tactical or firefighting gloves. It is the flexibility, lightness, and shock absorption that can withstand even the highest demands.

Usage:

- Production of tactical gloves.

Features:

- Lightweight - besides being lightweight, it is soft and comfortable.

- Flexibility - returns to its original shape after absorbing impact.

- High level of protection - perfectly absorbs impacts.

Nomex®

Nomex® is a meta-aramid fibre that is inherently flame resistant. When Nomex® is exposed to intense heat, its fibres thicken and carbonise, absorbing heat energy. In addition, Nomex® does not melt, drip or support combustion. It is one of the most widely used materials for firefighting and tactical gloves. One of our suppliers is Fritsche Technical textiles from Germany.

Usage:

- Production of tactical gloves.

- Manufacture of firefighting gloves.

Features:

- High resistance to heat and flame.

- Good dimensional stability.

- Resistance to steam.

- Resistance to most chemicals, hydrocarbon compounds and other organic solvents.

- Abrasion resistance and high temperature tensile strength (>150 °C) better than synthetic fibre types.

- Easy to clean.

- Lightweight.

Kevlar®

Kevlar is a para-aramid fibre with resistance to heat, heat, abrasion and cutting. The fibre is extremely strong, yet lightweight, making it ideal in the manufacture of firefighting and rescue gloves. Our leading supplier is the German company Inventex

Usage:

- Production of tactical gloves.

- Manufacture of firefighting gloves.

Features:

- High heat resistance.

- Cut and abrasion resistance.

- Lightweight.

- High strength.

PBI®

PBI (polybenzimidazole) is an organic performance fiber with a very high decomposition temperature (>700 °C) and no melting point. It has exceptional thermal and chemical stability and does not readily ignite. It was originally developed for the NASA Apollo space programme. It is currently ideal for the manufacture of firefighting and tactical gloves.

Usage:

- Production of tactical gloves.

- Manufacture of firefighting gloves.

Features:

- High resistance to direct flame.

- High chemical stability - retains its rigidity.

- Non-melting even at high temperatures.

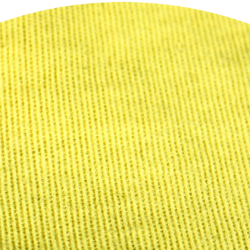

Porelle PU FR

Porelle® brand polyurethane membrane with flame retardant treatment combines comprehensive protection with high breathability and flexibility. The properties highly exceed the minimum requirements of EN 659 and NFPA 1971 for firefighting gloves.

Usage:

- Manufacture of firefighting gloves.

- Manufacture of firefighting boots.

- Production of tactical gloves.

Features:

- Protection against:

- Water (water column up to 7000 mm) and water vapour and wind.

- Chemicals (ASTM F903).

- Pathogens and bacteria (ISO 16604).

- High fire resistance and flame retardancy.

- High breathability with Ret < 7 according to ISO 11092.

- Very good sensitivity and strength.

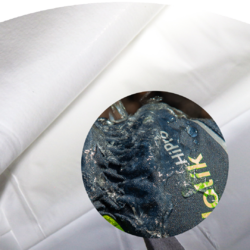

Porelle PTFE

The PTFE bicomponent Porelle® membrane with flame retardant treatment combines complete protection with high breathability and low adhesion. The properties highly exceed the minimum requirements of EN 659 and NFPA 1971 for firefighting gloves.

Usage:

- Manufacture of firefighting gloves.

- Manufacture of firefighting boots.

- Production of tactical gloves.

Features:

- Protection against:

- Water (water column up to 7000 mm) and water vapour and wind.

- Chemicals (ASTM F903).

- Pathogens and bacteria (ISO 16604).

- High fire resistance and flame retardancy.

- High breathability with Ret < 7 according to ISO 11092.

- Very good sensitivity and strength.

Ceramic

The unique coating of Nomex material with ceramic increases its resistance to mechanical hazards, especially in the exposed parts of the gloves and thus significantly extends their life. The special tread structure of the ceramic layer allows great flexibility of the glove and protection for the user.

Usage:

- Manufacture of firefighting gloves.

Features:

- Protection against mechanical hazards:

- Abrasion.

- Cutting.

- Pathogens and bacteria.

- Extends the life of materials.

- Replaces reinforcements - functions are preserved.

- Increases flexibility and reduces glove weight.

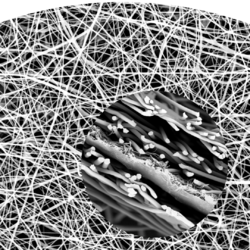

NANO

The unique polymer-based nanofibre structure is sourced and manufactured in the Czech Republic. The nanofiber layer guarantees a superior filtration efficiency, 99.9 % to trap viruses, bacteria and dust particles. The excellent breathability of the material (200 l/m²/s), allows easy breathing, comfort even during long term use. It serves to protect against bacteria, viruses and dust particles.

Usage:

- Production of face masks.

Features:

- Material captures over 99.9% of all bacteria, viruses and dust particles.

- Protection against blood and other type IIR droplets.

- All day use.

EXPLORER Sole

The highly durable rubber outsole combines a number of unique features such as a self-locating tread, shock absorber, specially profiled anti-slip zones, ergonomic shape for proper footing and roll.

Usage:

- Manufacture of firefighting boots.

Features:

- Comfort - the width gives room to the toes and joints.

- Resistance to acids, fuel and oils.

- Stability when walking and running - unique stabilizing elements and toe assistance.

- Unique features - Shock absorber, reflective elements, anti-slip profile.

- Heat resistance 250°.

YUMA

Polyurethane microporous membrane with high water resistance and breathability. Our stable supplier of this material is Accoppiatura from Italy.

Usage:

- Manufacture of firefighting boots.

Features:

- Water resistance.

- High level of breathability.

- Very good water column height to breathability ratio.

- Comfortable design thanks to foam padding.

Topaz bimicro®

PTFE hydrophilic membrane with high water resistance and breathability. This unique material comes from Germany.

Usage:

- Manufacture of firefighting boots.

Features:

- Water resistance.

- High level of breathability.

- Very good water column height to breathability ratio.

- Comfortable design thanks to foam padding.